Click Here to go to the full story posted by Autodesk

Undersea design adventure Project.

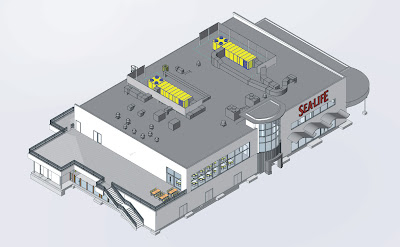

With Revit® MEP software, Design West Engineering completes construction documents for the SEA LIFE™ Aquariumat LEGOLAND®.

Design West Engineering Customer Success Story

Revit® MEP Revit®

For our clients using Revit Architecture, our original

goal was to produce 100 percent of our construction documents with Revit

MEP and we’ve already accomplished that. It really does help us run a much

tighter project and put a better product into the field. The 3D models give the

entire design team — from the project engineer on down — adramatically improved

understanding of the building. As a result, contractors can build our projects

more easily and with far fewer questions.Robert CronkPrincipalDesign West Engineering

Firm Summary

Design West Engineering is a mechanical, electrical, and plumbing (MEP) engineering consulting firm based in San Bernardino, California. Established in 2000, the firm delivers services to clients from a wide range of building sectors, including higher education, K–12 schools, religion, and civics. “We’ll tackle almost any type of commercial engineering or energy-efficiency project,” says Robert Cronk, a principal at the firm. “Lately, we’ve also done quite a bit of multifamily residential work.” Until early 2007, Design West relied primarily on AutoCAD® software to deliver exceptional service and designs to its architectural partners. “However, we began to notice that more and more architects were using Revit Architecture software and becoming quite passionate about wanting to collaborate with us via a complete building information model.” As a result, Design West began migrating to Revit MEP software, the intuitive building information modeling (BIM) solution built specifically for MEP engineers and designers.

Design West Engineering is a mechanical, electrical, and plumbing (MEP) engineering consulting firm based in San Bernardino, California. Established in 2000, the firm delivers services to clients from a wide range of building sectors, including higher education, K–12 schools, religion, and civics. “We’ll tackle almost any type of commercial engineering or energy-efficiency project,” says Robert Cronk, a principal at the firm. “Lately, we’ve also done quite a bit of multifamily residential work.” Until early 2007, Design West relied primarily on AutoCAD® software to deliver exceptional service and designs to its architectural partners. “However, we began to notice that more and more architects were using Revit Architecture software and becoming quite passionate about wanting to collaborate with us via a complete building information model.” As a result, Design West began migrating to Revit MEP software, the intuitive building information modeling (BIM) solution built specifically for MEP engineers and designers.

The Challenge

Since adopting Revit MEP, Design West has completed construction documentation on 14 major projects, including the 28,000-squarefoot SEA LIFE Aquarium at LEGOLAND near San Diego, California. “SEA LIFE is designed to introduce children to the wonders of the ocean,” says Cronk. “There’s a whole chain of them across Europe, but this project is their first U.S. venture.”

Since adopting Revit MEP, Design West has completed construction documentation on 14 major projects, including the 28,000-squarefoot SEA LIFE Aquarium at LEGOLAND near San Diego, California. “SEA LIFE is designed to introduce children to the wonders of the ocean,” says Cronk. “There’s a whole chain of them across Europe, but this project is their first U.S. venture.”

“The whole park is very heavily themed, with lots of exposed ductwork and piping that must be painted or covered with theming,” says Cronk. When designing SEA LIFE locations throughout Europe, the project architect used Revit® Architecture software. “However, because the MEP engineers on those projects were still using traditional CAD applications, they sent him 2D ductwork drawings. As a result, before the theming contractors could decorate any of the spaces, the architect had to provide interior elevations of every single wall in all of the attraction rooms so they could estimate the proper duct heights.”

Revit MEP provides instant design feedback— not a large set of error-prone documents for after-the-fact examination.

Revit MEP provides instant design feedback— not a large set of error-prone documents for after-the-fact examination.

Architects are obviously concerned with aesthetics; our initial requirement is to make sure the system works properly. The Revit platform enables both of us to do our respective jobs better.Jarrod BaumannProject Manager

Design West Engineering

The Need for Speed

All of that work was time consuming and not very accurate. Yet the SEA LIFE project was on a fasttrack construction schedule and could not afford any delays or possible design errors. “We broke ground in late November,” says Cronk. “The goal is to have the project fully operational in late June and open to the public in time for the July 4 weekend.”

All of that work was time consuming and not very accurate. Yet the SEA LIFE project was on a fasttrack construction schedule and could not afford any delays or possible design errors. “We broke ground in late November,” says Cronk. “The goal is to have the project fully operational in late June and open to the public in time for the July 4 weekend.”

An Information Disconnect

“In the construction process, there’s often a disconnect between the information we provide the

architects and what they really understand about the ductwork systems,” says Jarrod Baumann, a project manager at Design West. “Often, we don’t resolve that disconnect until after construction begins. With Revit MEP, we hope to greatly increase the architects’ understanding of our projects long before we get to the fi eld. We want them to know exactly where our ducts are going to run and how they’ll interact with a building.”

“In the construction process, there’s often a disconnect between the information we provide the

architects and what they really understand about the ductwork systems,” says Jarrod Baumann, a project manager at Design West. “Often, we don’t resolve that disconnect until after construction begins. With Revit MEP, we hope to greatly increase the architects’ understanding of our projects long before we get to the fi eld. We want them to know exactly where our ducts are going to run and how they’ll interact with a building.”

The Solution

Right from the start, Revit MEP and its intuitive tools for system design and analysis enabled Design West to save valuable time. “The principal architect was absolutely tickled to receive our 3D Revit MEP model,” says Cronk. “He used Revit Architecture to cut a section from every single wall and quickly get all the information the theming team needed to do its job.”

Reduce Design Conflicts

“He was also able to interactively check to make sure no future confl icts existed,” says Cronk. “We already knew that we didn’t have any confl icts with the building structure, but he was able to verify that there would be no problems with the theming and the ductwork. That was a very big benefit.”

Easily Visualize MEP Designs

“Revit MEP also enabled the architects to easily visualize our designs,” says Baumann. “Architects are obviously concerned with aesthetics; our initial requirement is to make sure the system works properly. The Revit platform enables both of us to do our respective jobs better.”

Create More Accurate Designs

“Because the architects can easily see where we want to place a unit, how big it is, and what it looks like, we can quickly make adjustments based on their input,” says Cronk. “Plus, the Revit platform itself gives us instant design feedback rather than a large set of documents that someone has to carefully examine for accuracy much later. That helps us make better decisions and increases the likelihood that our MEP systems will fi t the building in the best possible way.”

Increase Understanding

“As a result, we’re starting to see that the architects have a much better understanding of our discipline,” says Cronk. “To give a specifi c example, one of our clients does a lot of multi-family residential work with Revit Architecture. Those types of buildings have very tight space constraints on the mechanical systems. Using our model, the architects easily produced shafts and soffi ts for ductwork right around the work we gave them. They absolutely loved this capability.”

Build Credibility

“Another benefi t is added credibility with the architects,” says Cronk. “Sometimes it seems as if they think we’re crying wolf when we ask for more duct space. With Revit MEP, we can quickly show them exactly where all of the space is getting chewed up. The whole interaction is more efficient and we’re able to move forward that much faster. That’s a huge benefit.”

“Another benefi t is added credibility with the architects,” says Cronk. “Sometimes it seems as if they think we’re crying wolf when we ask for more duct space. With Revit MEP, we can quickly show them exactly where all of the space is getting chewed up. The whole interaction is more efficient and we’re able to move forward that much faster. That’s a huge benefit.”

Share a Common Model

Design West also worked closely with the SEA LIFE project’s structural engineers. “More often than not, if we have a problem fi tting the ductwork on a project, it involves the structural cavities,” says Baumann. “We used Revit MEP to determine whether we had enough space for ductwork or adequate clearance in various spaces throughout the entire project.”

Clearly Communicate Design Intent

Even on a much smaller scale, Design West has found tremendous benefi t in Revit MEP software’s 3D visualization capabilities. “For example, we recently designed a small retail space,” says Cronk. “The owner was interested in how the different displays were going to look. He was very pleased to be able to sit down in front of the 3D model, interact with it, and see exactly how the space and diff erent light fi xtures would appear in real life.”

Reduce Costs

“Based on what he learned in that meeting, the owner made signifi cant changes to the light fixtures,” says Cronk. “Because he also received some budgetary feedback from the model, he decided to cut costs by changing some of his lighting selections.” Design West also helped one of its architectural clients, WLC Architects, save money on the design of its new 60,000-square-foot offi ce building. “Using the information in our Revit MEP model, the architects were able to determine the actual cost of several different lighting packages and make appropriate budgetary decisions,” says Cronk. “They also chose the fi xtures that looked best in the space.”

Practice Green Design

“That particular offi ce building is going for LEED certification,” says Baumann. “As a firm, we’re

involved in several other sustainable design efforts, such as the Collaborative for High Performance Schools (CHPS), a spinoff of LEED focused primarily on schools. Currently, we’re designing a combination high school and middle school campus. The client wants to score incredibly high on the CHPS checklist and plans on using the Revit platform to accomplish a substantial portion of that.” In particular, Design West is experimenting with exporting geometry from Revit to various software packages for heating/cooling and lighting analysis, such as eQuest, IES Virtual Environment, and AGI 32, either with direct export/import or through GBXML.

Transform Attitudes

Revit MEP software’s 3D capabilities have had a profound impact on contractors. “One of our project managers recently presented 3D designs to a contractor who’s been building multifamily residential homes from 2D documents for more than 20 years,” says Cronk. “At first, he wondered why we’d even bothered to use 3D.”

Revit MEP software’s 3D capabilities have had a profound impact on contractors. “One of our project managers recently presented 3D designs to a contractor who’s been building multifamily residential homes from 2D documents for more than 20 years,” says Cronk. “At first, he wondered why we’d even bothered to use 3D.”

Maximize Coordination

The fi rm’s ultimate goal is to receive very accurate structural models at the same time that it receives the architectural models. “That really enables us to do our jobs well,” says Baumann. To further minimize design coordination errors on the SEA LIFE project, Design West regularly updated its model via links to the architectural building model, the structural framing model, the aquarium tanks, and the underground tanks.

Intuitively Create MEP Systems

“At one point on the SEA LIFE project, we got into a real time crunch,” says Cronk. “The owners made dramatic changes at a time when we had pressing deadlines on other projects. Because our entire offi ce wasn’t yet trained on Revit MEP, I produced some of the immediate changes in AutoCAD to get us past the hurdle.” Later, when engineers input Cronk’s changes into the Revit model, they quickly noticed several ways to improve the AutoCAD-produced design. “Being able to spin the model on-screen made me feel like I was at the job site discussing ways to save money with the contractor,” says Baumann. “Using Revit MEP, it’s easy to take that kind of step in the office— long before getting to the field.” “But by the end of the meeting, he had to admit

that it really helped him visualize the lighting for the parking lot and courtyards,” says Cronk. “He also admitted that 3D would be even more helpful to someone without his skills. Even with his level of experience, he still thought that 3D was worthwhile— even if it required extra effort.”

Improve Workflows

As a direct result of using Revit MEP, Design West modifi ed its workfl ow in several important

ways. “For one, our project manager and Revit trainer is very quickly moving into the role of BIM manager,” says Cronk. “His job is to oversee the quality and content of the model and to make sure that it works across the entire Revit product family— throughout our office and with our partners.”

Subscribe for Maximum Benefit

After receiving early training at Autodesk University, Design West chose to participate in the Revit MEP subscription program. “There’s definitely a benefit to being able to keep up with the latest release,” says Cronk. “We also get access to additional helpful information and quick responses from the online product support team. Our subscription has been very useful to us; we certainly don’t intend to do it any other way.”

The Result

“We’re really excited,” says Cronk. “Our original goal was to produce 100 percent of our construction documents with Revit MEP for our clients using Revit Architecture and we’ve already accomplished that. It really does help us run a much tighter project and put a better product into the fi eld. The 3D models give the entire design team—from the project engineer on down—a dramatically improved understanding of the building. As a result, contractors can build our projects more easily and with far fewer questions.”

“We’re really excited,” says Cronk. “Our original goal was to produce 100 percent of our construction documents with Revit MEP for our clients using Revit Architecture and we’ve already accomplished that. It really does help us run a much tighter project and put a better product into the fi eld. The 3D models give the entire design team—from the project engineer on down—a dramatically improved understanding of the building. As a result, contractors can build our projects more easily and with far fewer questions.”

Our marketing director says that the best thing he can tell

an architect is that we use Revit MEP. We’re currently really well positioned in

the marketplace and have a distinct competitive advantage—particularly because

most other MEP firms can’t provide these services yet. We wouldn’t have that

advantage without Revit MEP.

Robert Cronk

Principal

Design West

Engineering

Hi,

ReplyDeleteThere is an easy way to get jobs in Hyderabad, just post your resume in usjobcareer.com and got your dream job.

great post.thank u for this ........

ReplyDelete